What Defines a High-Performance PEM Electrolyzer Component?

A high-performance PEM electrolyzer component supports efficient hydrogen production, maintains low resistance, and operates reliably in high-pressure environments. These components must make strong contact with the catalyst-coated membrane (CCM), distribute current evenly, and hold up under constant thermal and mechanical stress.

What high-performance components do well:

- Increase electrical conductivity

- Improve catalyst contact and efficiency

- Support consistent gas and water flow

- Operate reliably under long-term use and pressure

Why Efficiency Matters in PEM Electrolyzers

PEM electrolyzer efficiency directly affects the cost and scalability of green hydrogen production. In simple terms, efficiency determines how much electrical energy is required to generate one kilogram of hydrogen. Since electricity is often the most expensive input in hydrogen production, even small improvements in efficiency can result in meaningful cost savings, especially at scale.

Improving efficiency isn’t about just saving money. It is also critical for increasing the overall output of hydrogen systems, reducing waste, and making green hydrogen a viable energy source for sectors like automotive, power generation or aerospace. As hydrogen demand grows, system-level efficiency will become a key differentiator for OEMs and integrators.

Several factors within the electrolyzer stack influence performance:

- Contact Resistance Between Layers

When internal layers don’t align properly or lack uniform contact, resistance increases. This added resistance leads to energy loss in the form of heat and reduces the current density that can pass through the stack. Materials that provide smoother surfaces and better contact with the catalyst-coated membrane help minimize these losses. - Gas and Water Transport

Efficient mass transport is critical to keeping hydrogen and oxygen moving out of the cell and water moving in. Poorly designed flow fields or high tortuosity in the porous transport layer (PTL) can slow this process, creating bottlenecks that limit efficiency. Optimized mesh structures with controlled porosity allow for smoother, more consistent flow paths. - Catalyst Utilization

Catalysts are one of the most expensive parts of a PEM electrolyzer. Maximizing how effectively the catalyst is used can significantly improve cost-per-kilogram of hydrogen. Mesh layers that provide even, planar contact with the CCM help ensure the entire catalyst-coated surface is active, not just certain areas. - Mechanical and Thermal Stability

PEM stacks must operate under high differential pressures and frequent temperature changes. Components that degrade or shift over time can reduce performance and cause early system failure. Durable materials and consistent bonding processes help maintain stack integrity, providing efficiency over the system’s full lifespan.

In every case, the design, material choice, and manufacturing quality of each component influence how efficiently the electrolyzer performs. That’s why OEMs and system designers turn to trusted manufacturing partners like ACS Industries. The right components don’t just support efficiency; they make it possible.

Key Components That Improve Performance

Expanded Metal Flow Field Layers

ACS has developed an advanced expanded metal mesh solution for flow field layers, components that help direct gas and water flow across the membrane surface. Our expanded metal mesh delivers a smooth, flat contact surface that performs better across all key efficiency metrics.

We specialize in the design and production of titanium expanded metal, a preferred material for PEM electrolyzers due to its excellent corrosion resistance, high conductivity, and strength-to-weight ratio. This material choice plays a critical role in long-term stack stability and performance, especially in high-pressure and acidic environments.

Key advantages of our expanded metal flow field mesh include:

- Surface roughness measured in nanometers instead of micrometers

- Stronger contact with the catalyst membrane

- Distribution of current more evenly across the active area

- Reduced resistance and improved gas and water flow

- Consistent porosity and customizable pore structures

- Maintained strengthen and function at reduced thickness

By combining smart material selection with precise mesh designs, this flow field solution improves catalyst utilization, lowers energy loss, and helps extend the overall lifespan of the electrolyzer stack. Explore more about material section in our blog: Why Material Selection Matters for Hydrogen Electrolysis Systems.

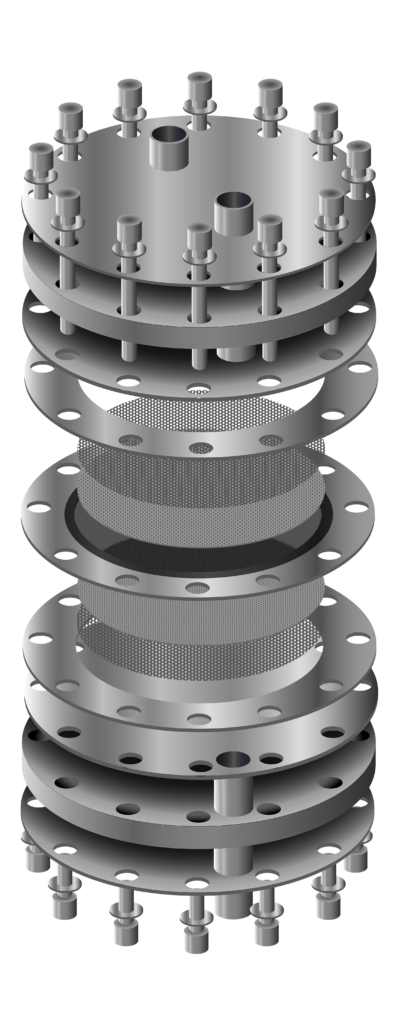

Precision-Engineered Stack Hardware and Bipolar Plates

ACS also manufacturers complete PEM stack hardware, including stamped bipolar plates, end plates, rods, and flat plates. We use advanced bonding and welding methods to assemble parts at scale, with tight tolerances that deliver consistency.

Each component is designed to support system-level performance. Our global production network allows us to deliver large volumes of parts with the precision, repeatability, and quality assurance needed for next-generation hydrogen systems. Contact our team to discuss your application needs.

Revolutionary Microexpanded Porous Transport Layers

ASC is developing a next-generation porous transport layer using microexpanded titanium mesh, a breakthrough technology supported by the U.S. Department of Energy. These PTLs are engineered to enhance hydrogen production efficiency by improving current distribution, water management, and catalyst layer utilization within the PEM stack.

Currently in advanced development, these PTLs are designed to be fully scalable and compatible with automated assembly processes. The project’s goal is to deliver a commercially viable solution that exceeds DOE performance benchmarks and significantly reduces the cost of green hydrogen production. The first product samples are slated for delivery in 2026.

Learn how ACS Industries leverages its extensive experience, efficient processes, and production scale to deliver cost-effective PEM electrolyzer components.

Frequently Asked Questions About Improving PEM Electrolyzer Efficiency

What is the most efficient PEM electrolyzer component?

Expanded metal mesh layers, especially those made from corrosion-resistant materials like titanium, are among the most efficient options available. These components offer better surface contact with the catalyst-coated membrane, improving current distribution and maximizing catalyst utilization. Compared to traditional sintered porous transport layers, they also allow for lower pressure drop and better gas and water management within the stack. The result is improved PEM electrolyzer efficiency with reduced energy loss and longer operational life.

How do electrolyzer components affect system performance?

Each component in a PEM stack plays a role in system-level performance. The PTL, bipolar plates, and end plates affect how current flows, how gases are removed, and how heat and pressure are managed. If any of these elements are poorly designed or inconsistently manufactured, it can lead to uneven catalyst usage, pressure imbalances, and electrical losses. High-performance components support efficient operation, minimize degradation, and ensure long-term stability, factors that are critical for scalable green hydrogen production.

What are porosity gradients, and how do they improve performance?

A porosity gradient means the pore size and density change across the thickness of the mesh. This design improves gas and liquid flow through the PTL, reduces flooding, and enhances water delivery to the catalyst layer. It also allows for better pressure control and uniform current distribution. By managing how fluids move through the system, porosity-graded materials help boost PEM electrolyzer efficiency and reduce wear on the catalyst.

Why is titanium used in PEM electrolyzer components?

Titanium is lightweight, corrosion-resistant, and highly conductive, making it an ideal material for harsh electrochemical environments like PEM electrolyzers. Titanium expanded metal is particularly useful for PTLs because it maintains structural integrity under high differential pressure, while also ensuring long-term chemical stability. ACS specializes in titanium expanded metal manufacturing and offers both standard and custom solutions.

What is diffusion bonding, and why does it matter?

Diffusion bonding is a solid-state joining method that creates a clean, highly conductive connection between metal parts without using traditional welding techniques. It improves mechanical strength and electrical conductivity while reducing the risk of contamination or thermal damage. In PEM electrolyzers, diffusion bonding supports efficient stack assembly and ensures that key components maintain performance over time. Learn more about ACS’ diffusion bonding expertise.

Does ACS offer custom PEM components?

Yes. ACS provides fully customizable PEM electrolyzer components, including mesh materials with controlled porosity, thickness, and conductivity. We work closely with OEMs and integrators to design components that align with their system architecture and performance goals. We also support custom bonding, welding, and full stack assemblies, helping reduce development time and manufacturing complexity. Reach out to speak with a member of our team.

Can ACS help reduce the cost of green hydrogen production?

Absolutely. By improving PEM electrolyzer efficiency and offering cost-effective alternatives to sintered PTLs, ACS helps reduce both the upfront and operational costs of hydrogen systems. Our vertically integrated approach also cuts down on lead times, waste, and variability, making it easier for our partners to scale clean hydrogen solutions for industrial, transportation, and energy applications.

ASC is developing a next-generation porous transport layer using microexpanded titanium mesh, a breakthrough technology supported by the U.S. Department of Energy. These PTLs are engineered to enhance hydrogen production efficiency by improving current distribution, water management, and catalyst layer utilization within the PEM stack.

Currently in advanced development, these PTLs are designed to be fully scalable and compatible with automated assembly processes. The project’s goal is to deliver a commercially viable solution that exceeds DOE performance benchmarks and significantly reduces the cost of green hydrogen production. The first product samples are slated for delivery in 2026.

Learn how ACS Industries leverages its extensive experience, efficient processes, and production scale to deliver cost-effective PEM electrolyzer components.

What Sets ACS Apart – And Where We’re Headed Next

ACS is the world’s largest vertically integrated wire mesh manufacturer, with the resources and experience to support electrolyzer OEMs and system integrators across the globe. Our combination of advanced materials expertise, scalable production, and in-house R&D sets us apart in a rapidly growing hydrogen economy. We offer:

- Custom mesh design and fabrication tailored to PEM system requirements

- High-volume production supported by a global manufacturing network

- Advanced bonding and welding techniques for complete stack assemblies

- Proven success in delivering durable, high-performance components at scale

Our commitment to innovation goes beyond manufacturing. ACS is leading several green development efforts, including a Department of Energy-funded project focused on advancing PEM electrolyzer technology. Our team is actively developing:

- Revolutionary alternative to sintered PTLs

- Mesh materials with engineered porosity gradients for improved gas and water flow

- Next-generation bonding techniques to enhance conductivity and mechanical stability

These innovations are designed to help customers improve efficiency, lower costs, and bring scalable green hydrogen solutions to market faster. From concept to final product, ACS delivers the technical leadership and production capacity needed to move the industry forward.

Contact our team to discuss your PEM electrolyzer component needs and discover how our range of solutions can optimize your project.