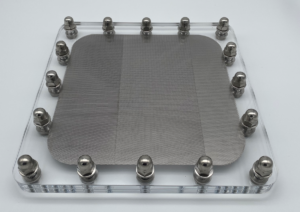

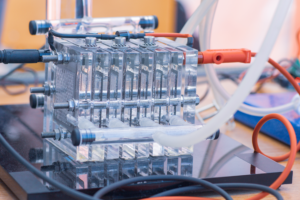

ACS is now leveraging our expertise in knitted wire mesh, woven wire, and expanded metal (including titanium expanded metal) to support Green Hydrogen Production, offering a wide range of hydrogen fuel cell components to meet the needs of our customers. Using our scale, experience and continuously improving process efficiency to drive down the cost of hydrogen production, ACS designs and produces anodes, cell components, stack hardware, and assemblies of PEM, Alkaline and Solid Oxide Electrolyzers.

Explore our range of hydrogen fuel cell components and contact our team today to discuss custom solutions for your project.

HYDROGEN ELECTROLYZER, FUEL CELL, AND BATTERY COMPONENTS THAT EXCEED EXPECTATIONS

PEM ELECTROLYZERS

ALKALINE ELECTROLYZERS

ENERGY STORAGE

FUEL CELLS

As an innovative and cutting-edge manufacturer of electrolyzer, fuel cell, and battery components, our team is shaping the future of green energy. With our expertise in engineering design and quality production at scale, we can create custom hydrogen electrolyzers to meet and exceed the needs of any of your green energy devices.

Leveraging cutting-edge technology, including diffusion bonding furnaces, and high-volume production expertise, we deliver customizable hydrogen fuel cell components that integrate seamlessly into your automotive, power generation, aerospace, or specialized application. Our rigorous quality control processes help ensure these components outperform industry expectations for durability, efficiency, and performance.

With our expertise in engineering design and quality production at scale, we can create custom components that improve the performance and drive down the costs of your electrolyzer stack.

Contact Our Experts About Our Hydrogen Fuel Cell Components and Green Energy Solutions

If you are searching for a reliable source for green energy components or would like to know more about our advanced solutions in the green energy sector, please contact us at:

Mack Huntsman

Application Engineer – Green Energy Division

email: [email protected]

phone: +1 801 388 3611