Titanium Expanded Metal Manufacturing

As a leader in expanded metal manufacturing, ASC Industries’ titanium expanded metal provides a best-in-class solution for applications in green energy, hydrogen fuel cells, and more, offering a compelling combination of strength, durability, and lightweight design.

Our engineers will work with you to understand your application requirements to manufacture the optimal product that meets your specifications.

Titanium Expanded Metal Solutions

At ACS Industries, we leverage our expertise in titanium expanded metal manufacturing to produce a range of high-performance products designed to meet the diverse needs of our customers:

- PEM electrolyzer flow fields – manufactured from expanded titanium

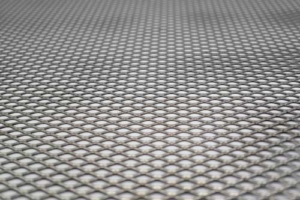

- Novel PTL components – manufactured from microexpanded titanium

- Variable expanded metal titanium filters – utilized in airbag and exhaust divisions

Commitment to Quality and Innovation

From raw material selection to final inspection, ACS Industries manufactures titanium expanded metal products that consistently deliver exceptional performance, longevity, and unmatched value. Our commitment to quality is evident in every stage:

- Material Selection: We source high-grade titanium and perform rigorous checks to ensure it meets our strict specifications.

- Precision Slitting and Shearing: Advanced machinery cuts titanium to exact dimensions, minimizing waste.

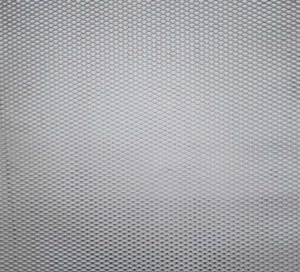

- State-of-the-Art Expanding: Our team utilizes cutting-edge machines for precise mesh patterns and dimensions, including our novel MicroExpanding™ machines recently developed by the ACS R&D team.

- Quality Control and Inspection: Throughout the process, we implement comprehensive quality control measures to deliver consistent product performance. Many of our expanding machines feature machine vision systems, enabling them to monitor and self-correct any production errors instantly.

- Flattening and Finishing: We offer customizable flattening and finishing options to meet specific needs for surface planarity, roughness, and cleanliness.

- Customizable Solutions: Talk to us about additional custom options, including:

- Thickness to optimize weight, permeability, and strength

- Mesh patterns with customizable porosity and tortuosity to achieve precise gas diffusion, pressure distribution, and fluid flow characteristics

- Surface treatments to bolster the titanium’s impressive resistance to corrosive environments

- Complex shapes to create intricate geometries, accommodating unique design requirements

- Thickness to optimize weight, permeability, and strength

Our R&D experts are always exploring new and innovative applications for titanium expanded metal in the every-evolving green energy sector. Contact us to discuss your application requirements.

Benefits of Titanium Expanded Metal

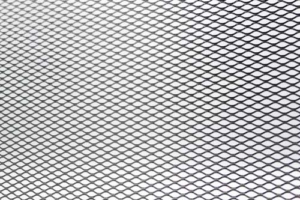

Titanium expanded metal is a durable material created by slitting and stretching sheets of titanium, forming a strong, open mesh with diamond-shaped openings. This process preserves the inherent properties of titanium while adding unique advantages compared to other expanded metals:

Superior Strength

Titanium boasts the highest strength-to-weight ratio of any common metal, meaning it’s incredibly strong compared to its weight. This allows for lightweight components without compromising performance. Expanded metal further enhances strength by distributing stress more evenly throughout the mesh.

Unmatched Corrosion Resistance

Titanium naturally forms a passive oxide layer that shields it from corrosion, even in harsh environments like saltwater or chlorine, making it ideal for applications where longevity and reliability are crucial. Other expanded metals, like steel or aluminum, can corrode, and can require additional coatings or treatments, depending on the application and operating environment. Those coatings can add cost and complexity.

Exceptional Temperature Tolerance

Titanium maintains its strength and stability over a wide temperature range, making it suitable for applications involving high heat or extreme cold. Some expanded metals can lose strength or wrap at high temperatures.

Custom Configurations

Titanium expanded metal can be tailored in its thickness, pattern and surface treatment to meet specific needs, allowing for precise control over factors like permeability, strength, and aesthetics, which can be limited with other expanded metals.

Lightweight Advantages

The low density of titanium can contribute to overall weight reduction in your application. This can be crucial for fuel cells, aerospace components, and other systems where weight is a critical factor.

Unlocking Performance in Hydrogen Fuel Cells with Expanded Titanium Metal

ACS Industries offers high-quality titanium expanded metal solutions specifically designed to enhance the performance and lifespan of critical components in hydrogen fuel cells. The unique structure of titanium expanded metal can elevate efficiency and durability in both:

- Gas Diffusion Layer (GDLs)

- The microscopic openings in our titanium mesh allow for optimal gas flow, maximizing fuel cell efficiency.

- Titanium’s exceptional heat resistance can help ensure GDLs withstand the demanding thermal environment within the cell.

- Chemical resistance protects the fuel cell’s internal components from degradation.

- Flow Field Plates

- The open mesh structure of our titanium expanded metal can significantly reduce weight compared to traditional solid plates.

- Excellent thermal conductivity effectively dissipates heat, which can help maintain optimal fuel cell operating temperature.

- Precisely machined channels in the titanium allow for customized gas flow optimization, which can maximize power output.

While the benefits listed are significant, the specific use of titanium expanded metal can vary depending on the component and technology. Whether it’s a PEM or Alkaline electrolyzer, or a Solid Oxide electrolyzer assembly, our manufacturing and engineering experts are here to help you find the right solution tailored to meet your application needs.

Talk to the Experts At ACS Industries

From prototype to mass production, our expanded metal manufacturing capabilities and expertise will help you meet your requirements, on time and on budget. Our team of experts is available to answer your questions about titanium expanded metal and help you find the right solution to meet your needs. Contact us today and let’s discuss your application requirements.