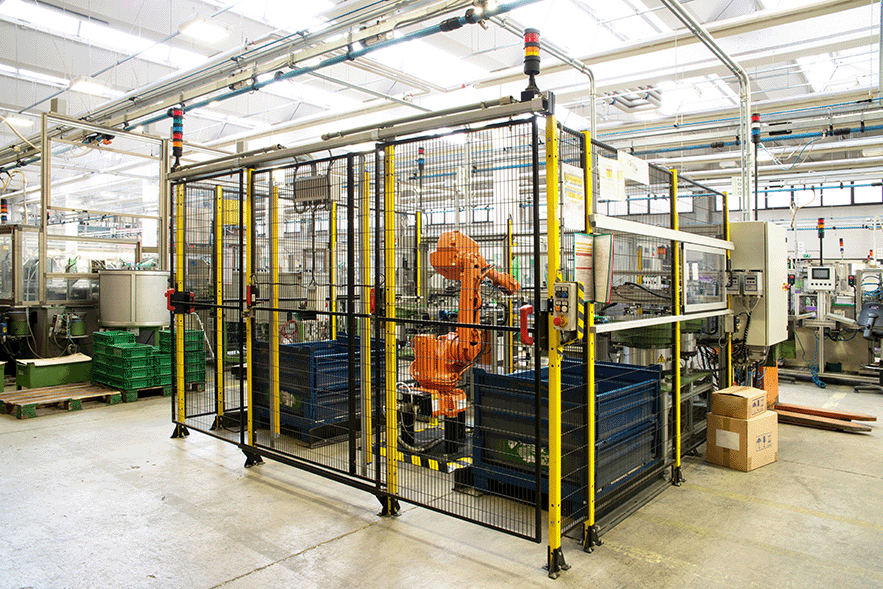

At ACS, we continue to expand the use of industrial automation to support stable production, reliable throughput and efficient workflows. Through a partnership with a global robotics firm, we are integrating advanced cobots and automation technology into many of our production cells to support more consistent, repeatable operations.

Backed by decades of experience serving some of the world’s largest OEMs and suppliers, ACS has developed manufacturing processes that deliver dependable, high-volume production. Our integrated operations, from in-house wire drawing to production and assembly, allow us to automate forming, shaping, welding and finishing processes for wire mesh components. These robotic systems produce mesh products in high volumes according to customer specifications and help reduce variation common in manual production.

Our unique combination of vertically-integrated operations and global manufacturing capabilities allows us to provide wire mesh automation solutions that support complex product requirements with dependable repeatability. From hydrogen energy systems and advanced insulation to specialized automotive components, we work closely with OEMs and Tier suppliers across a wide range of applications.

Through ongoing process refinement and the integration of automated systems, ACS supports the transition from prototype to production-ready mesh solutions. Our focus on scalable manufacturing methods helps customers bring innovative designs to volume production with confidence. Contact us today to see how our wire mesh automation capabilities can support your needs.

The ACS Advantage in Industrial Automation

Implementing industrial automation solutions involves more than integrating machinery. At ACS Industries, our experienced team works to optimize processes – leveraging advanced wire mesh automation technology with efficient operations, inline checks and rigorous quality controls which help to ensure consistent production and compliance with complex manufacturing requirements. Our strategic use of robotics and integrated systems offers measurable advantages including:

- Unmatched Quality Control: Automated vision systems and robotic equipment help reduce variation in repetitive tasks and support consistent inspection and part handling across production runs.

- Scalable Production: Our automated production cells are built for speed and efficiency, allowing us to seamlessly scale from pilot programs to large production runs without compromising quality or lead times.

- Traceability and Compliance: Components manufactured within our automated cells can feature comprehensive data logging and traceability, providing the quality documentation needed for many automotive and green energy applications.

- Cost-Effectiveness: By optimizing cycle times and reducing material waste, automated processes can contribute to a more efficient cost structure for complex or high-volume components.

Explore our range of capabilities and reach out to our team about your project needs.

Wire Mesh Automation FAQs

How does your industrial automation improve the quality of components?

Our industrial automation solutions use precision robotics and integrated sensors to perform tasks such as welding, assembly, handling and quality checks for wire mesh components and other custom manufactured parts. These systems maintain dimensional consistency, reduce process variation and promote stable quality across large production volumes.

What type of production volumes can your automated cells support?

ACS’s automated production cells are designed to support a wide range of volume requirements for wire mesh manufacturing and other component types. They accommodate mid-volume programs as well as continuous, large-scale production runs for global OEMs.

How quickly can you integrate automation for a new prototype?

Leveraging our established partnership with a global robotics firm, we can quickly adapt and program existing automation platforms. Our goal is to minimize the time between design finalization and full-scale automated production, accelerating your time-to-market.

Is industrial automation only used for your automotive components?

While our foundational experience is in automotive, our industrial automation solutions are deployed across other critical component sectors we serve, including green energy, industrial filtration, and general industrial manufacturing where precision, efficiency and quality are essential.

How does wire mesh automation maintain quality and consistency across ACS’s global facilities?

ACS implements the same proprietary industrial automation solutions and integrated quality control protocols across our global production cells, including those in China, Mexico and Romania. This uniformity, driven by identical robotic programming and automated vision systems, helps the wire mesh we manufacture to meet the same strict dimensional tolerances and performance standards, regardless of the factory location.

Partner with ACS for Wire Mesh Automation Solutions

By partnering with ACS, you gain access to wire mesh automation capabilities supported by a vertically integrated manufacturing model. Our use of advanced robotics and standardized quality-control processes helps maintain stable production, support consistent output and accommodate a wide range of project requirements. Contact our team to discuss how our automated manufacturing capabilities can support your next application.