LEADING AFTER-TREATMENT & EXHAUST EMISSION CONTROL MANUFACTURER

For more than four decades, ACS Industries has been a leading exhaust emission control manufacturer, supplying exhaust emission control and after-treatment system components for automotive OEMs and Tier I suppliers. Our expertise dates to 1975, when we introduced our innovative knitted wire mesh support systems. Today, our components play a vital role in controlling emissions in both on and off-highway vehicles worldwide.

ACS Industries’ after-treatment exhaust system mounting components can significantly reduce your emissions footprint. Explore our advanced automotive exhaust emission solutions below and contact us to discuss how we can support your compliance journey.

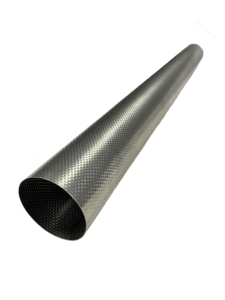

Micro- Louvre

As an innovative exhaust system components manufacturer, ACS Industries is now offering an alternative to legacy perforated tubes for exhaust applications. Our new Micro-Louvre tubes optimize the balance between weight and open area for improved acoustic performance.

Hot End Exhaust Seals & Gaskets

From our gas-tight, patented V-Seal technology to engineered axial support ring, these compressed knitted wire mesh elements can be tailored to meet specific gas leakage and mounting pressure requirements.

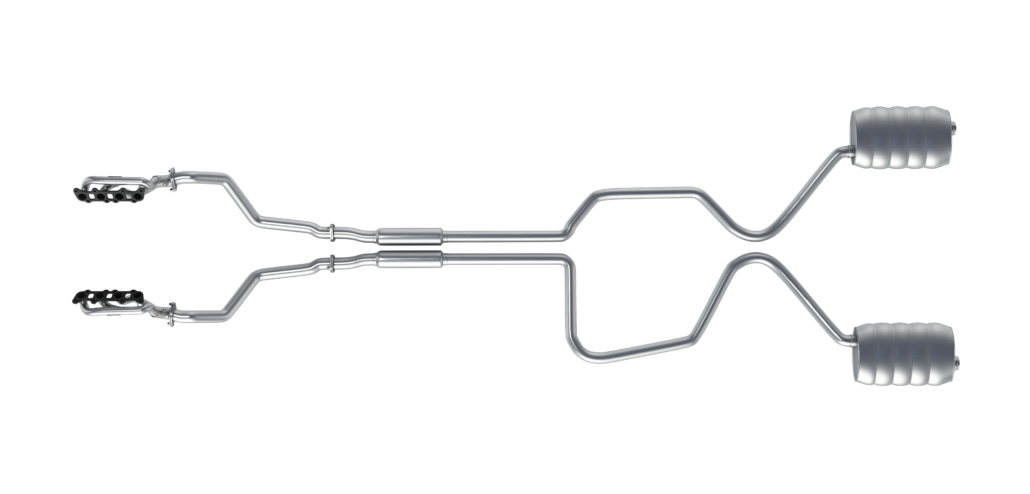

Wastegate & Active Exhaust Bushings

Knitted mesh can also be combined with graphite and mica for bushing solutions, effective to facilitate rotation and lubricity in turbocharger wastegates and active exhaust systems.

Mixers & Thermal Insulators

As global emissions requirements continue to tighten, the demand for various after-treatment systems will grow. Our advanced automotive emissions solutions, including our mesh mixer (right), diffuses the flow of injected urea, enabling reduced tailpipe emissions.

Cold End Seals & Gaskets

At ACS, we produce compressed, knitted wire mesh elements. These are inserted between the pipes to act as a cushion from shock and vibration, as well as to absorb any thermal expansion differences.

Muffler Components

Our High-Performance Muffler Sleeves represent the next step in muffler packing technology. As an experienced exhaust emission control manufacturer, we offer all of the acoustic properties of steel wool with the strength and durability of mesh for superior longevity.

DPF/SCR Retainer Rings

ACS manufacturers both radial & axial mesh retainer rings to protect & support ceramic substrates for gasoline or diesel after-treatment systems.

Your Trusted Exhaust System Components Manufacturer: Contact Us

Reach out today to leverage our exhaust emission control and after-treatment system component expertise. We will work closely with you to identify the optimal automotive emissions solutions for your unique challenges, helping to achieve compliance while minimizing your environmental impact. Fill out our contact form below, or to learn more about our automotive products, contact:

Scott Mackenzie

Vice President Business Development – Automotive

Email: [email protected]

Phone: +1 401-229-9459