At ACS, we are the world’s preeminent manufacturer of pyrotechnic airbag inflator filters, coolants, and cushions. Additionally, we are the only one to offer all the preferred filter media of knitted wire mesh, woven wire mesh, micro expanded metal, and sintered wound-wire. Although our designs are used primarily to cool and remove particulate from post-combustion inflation gas flow, some may also serve as propellant retainers. All of these mentioned elements are critical to safe and effective airbag deployments. In addition to recommending a filter media for a specific application, our design and applications engineers also design all tooling and most required production equipment in-house. Due to our fully-staffed, in-house machine shop, our tooling lead times and costs are the most competitive in the industry.

Airbag Filter Technologies

Helping You Meet USCAR

ACS pyrotechnic airbag inflator filters offer the following advantages over the competition:

Reduced Inflator Open Flame

VEM technology prevents burning pyrotechnic particles from escaping the filter.

Reduced Inflator Tank Wash

ACS is able to reduce the tank wash over a normal wire mesh filter by up to 50% using VEM technologies. This results in cleaner and safer airbag inflator.

Reduced Airbag Cushion Damage

Excess cushion and pin hole burns are typically the result of burning particles that escape a filter: a problem typical in traditional laminar flow filter

technology but solved with ACS’s VEM technology.

Adjustable for Specific Combustion and Performance Gates

ACS engineers can quickly adjust the filter’s internal combustion pressure and the tank ballistic performance gates with minor filter changes to

meet a customer’s acceptance gates, most often without major generate nor propellant load changes.

VEM Filters

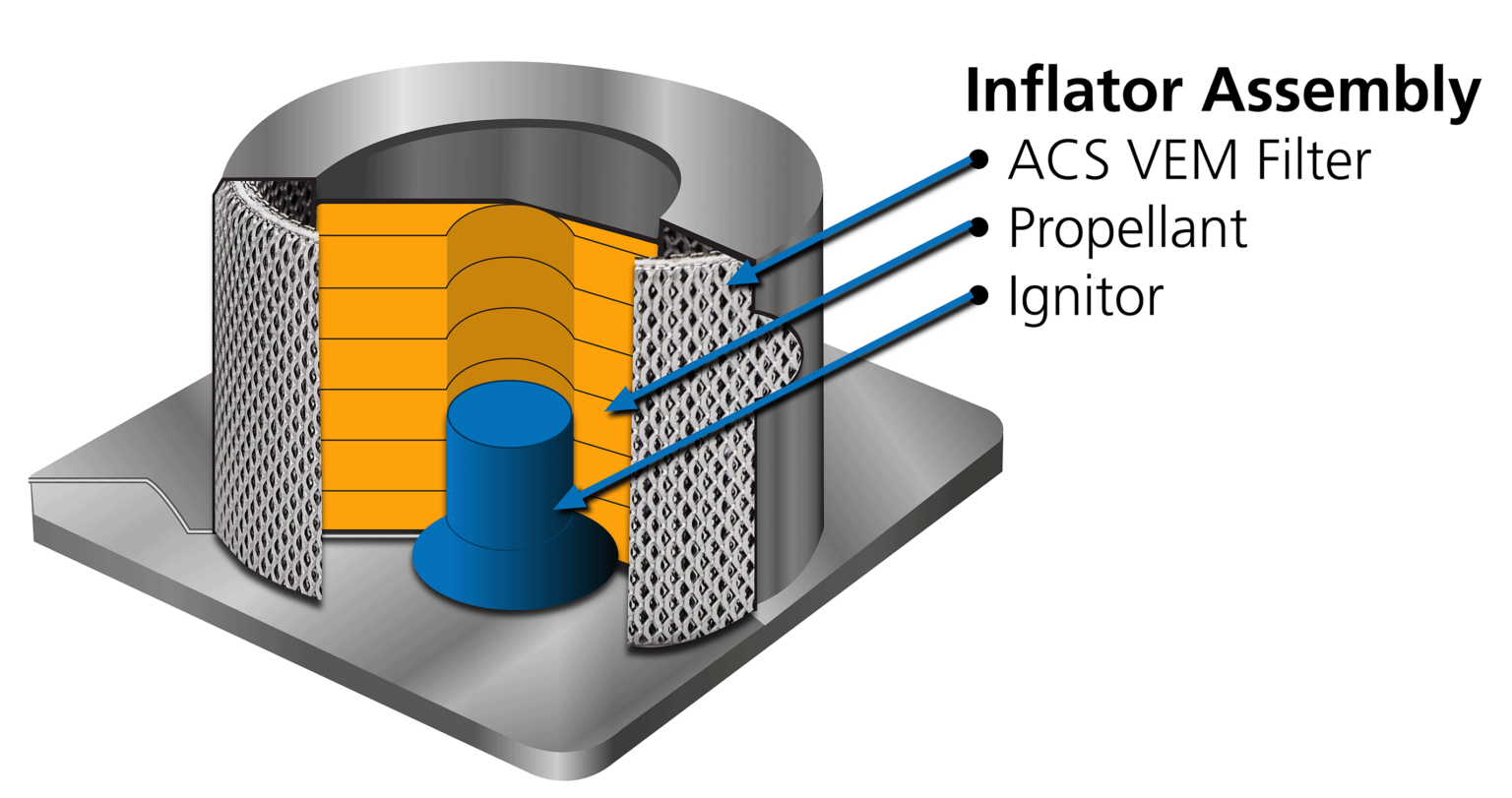

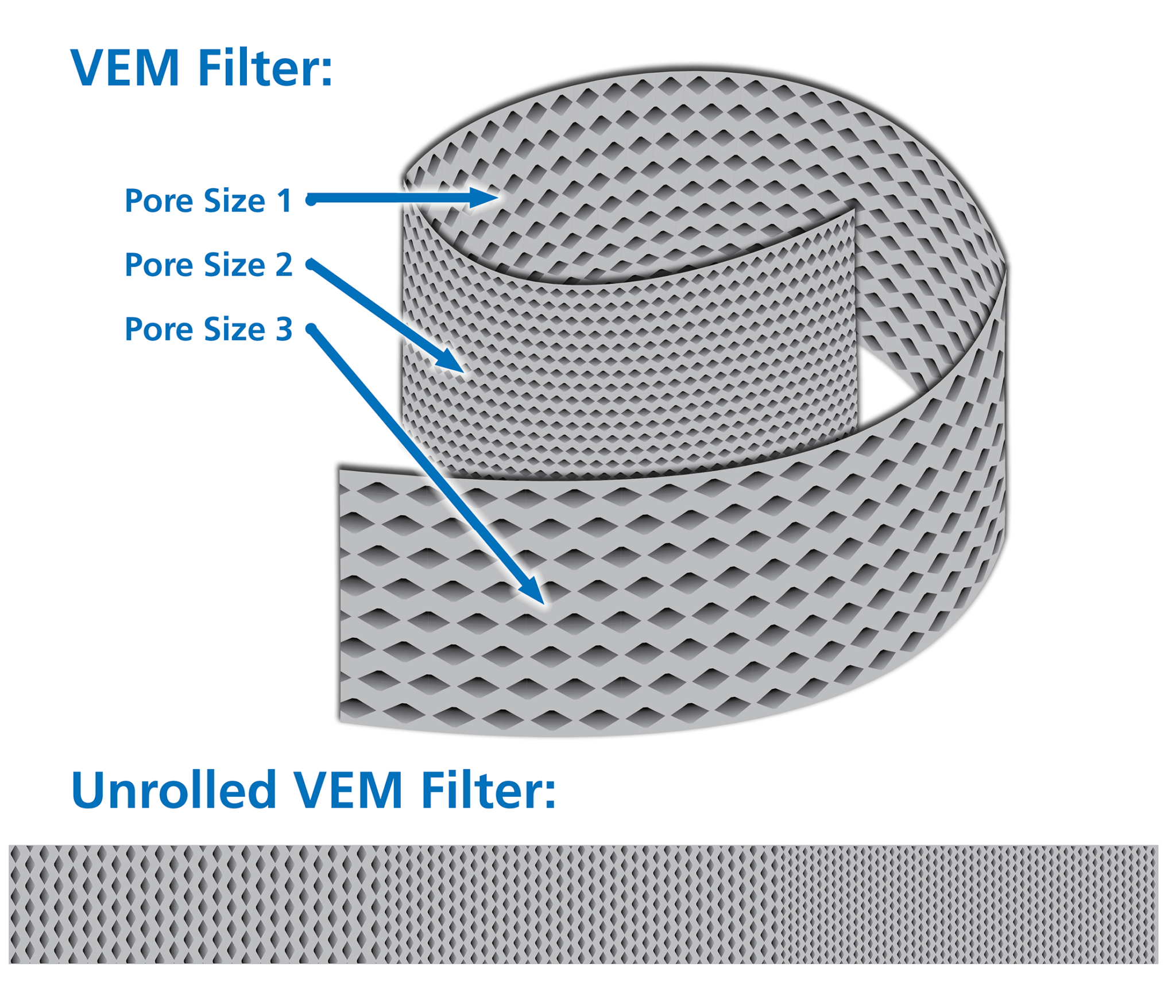

ACS’s patented Variable Expanded Metal (VEM) filters are constructed from a single sheet of expanded metal and combined with woven mesh when needed. Multiple layers of expanded metal are stacked, each with different hole counts and hole sizes, creating a more turbulent flow through the filter and preventing bag burns.

Inflators that fill the bag with pyrotechnics produce a burning jet fire. The jet fire is filled with copper and other molten metals that must be cooled and plated without exiting the inflator. If the filter has the same hole profile in all layers, then negative laminar gas flow is obtained, especially when the layers nest, creating direct flow paths for the burning jet fire particles to exit the inflator.

ACS filters use flow profiles that reduce the open flame by capturing all larger burning particles before they can exit the filter and the inflator; in all radial gas flowing and most axial gas flowing inflators. The result is cooler exit gas temperatures, and a cleaner, safer gas filling the airbag cushion.

Adjustable for Specific Inflator Combustion & Tank Performance Gates

ACS believes that filters for airbags are not heat sinks nor are they coolants, which function using convection heat transfer. A fast Mach gas velocity deployment time of less than 40ms invalidates the heat sink concept, making normal convection heat transfer formulas non-relevant. ACS believes the filter’s cooling is thus not based upon convection cooling; inflator performance is solely based upon the principles of thermodynamic cooling.

Rather than a coolant or a heat sink, ACS thinks of airbag inflator filters as thermodynamic diffusers. With this classification in mind, an engineer can quickly adjust both the filter’s internal combustion pressures and the tank’s ballistic performance gates with minor modifications. In this way we can meet a customer’s acceptance gates, most often without major generate nor propellant load changes. When designing a filter as a thermodynamic diffuser instead of a heat sink, the filter can become a much better generate slag trap, which helps to reduce overall inflator cost.

New Technology

Not only can we reduce the weight of a filter by as much as 50% below that of traditional wire mesh filters, making the inflator more sustainable by removing excess weight, but we can also allow inflator designers to engineer smaller, lighter, inflators with identical or improved cushion fill output volumes. These new technologies include, VCEM (Variable Crimped Expanded Metal), DFEM (Directional Flow Expanded Metal) and Ultra-lite VEM (or Variable Expanded Metal that removes 30-50% of the mass vs. traditional straight expanded metal filters).

Prototyping

ACS has a world class prototype filter department and software modeling technology to quickly help you design and alter the filter to meet your customers’ requirements and save development costs and reduce inflator cost as new inflator development takes time and costs are high. Please ask us about anything airbag filter related and we can help.

Seat Belt Cable Assemblies

Based on our extensive history in the OSS market, we have developed the following robust, well-tested process to manufacture flexible bracket parts:

- Tool controlled dimensions and critical features

- 100% inline part inspection with one-piece flow

- Integrated poka-yokes throughout the production process

Thermal Runaway Collars

We have taken the expertise gained through decades of leading the Pyrotechnic Airbag Inflator Filter market and applied it to thermal runaway protection for electric vehicle batteries.

Our Thermal Runaway Collars consist of:

- Expanded metal manufactured with our patented Variable Expanded Metal™ process or

- Crimped knitted mesh

Offering the benefits of:

- Jet flame elimination

- Low backpressure

- Prevents chain reactions across battery cells

- Protects battery housing from damage

- Greater safety for electric vehicle operators

Pyrotechnic Disconnect Switch Filters

The batteries and wiring of an electric vehicle can be damaged in a crash. This could potentially expose passengers, first responders, and others to dangerously high voltage. A pyrotechnic battery disconnect can cut the circuit, eliminating the danger, in less than one millisecond. This component makes a huge difference in the safety of electric vehicles, but the disconnect switch itself releases a strong light arc when the circuit breaks. This emitted energy can be quenched by ACS filters.

ACS is the only supplier of this component that offers all the preferred metallic porous materials including knitted wire mesh, woven wire mesh, and expanded metal. Our decades of experience leading the market in pyrotechnic airbag inflator filter technology has provided us with invaluable expertise regarding the optimal construction of these heat-sink filters in terms of performance, cost, and conformity at scale.