ACS Industries Electrolyzer Component Products

ACS is now leveraging our expertise in knitted wire mesh, woven wire, and expanded metal (including titanium expanded metal) to support Green Hydrogen Production.

We offer a wide range of hydrogen fuel cell components to meet the needs of our customers.

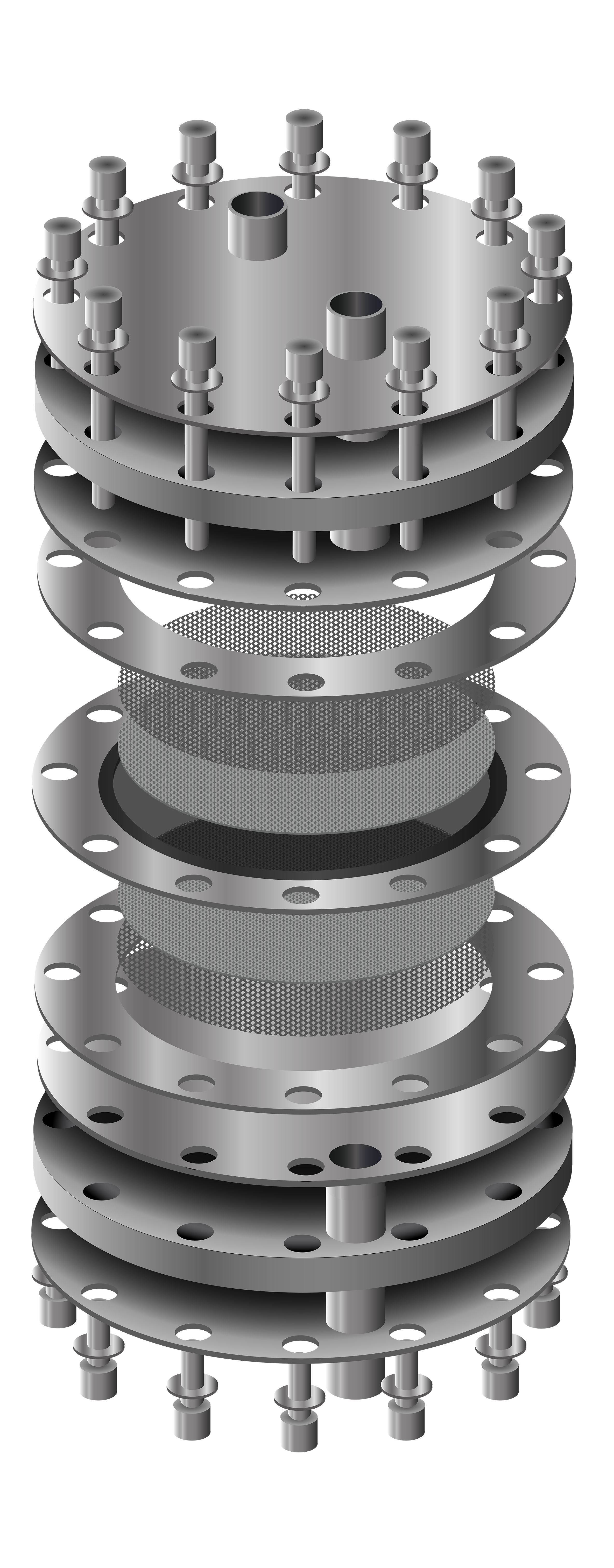

Using our scale, experience and continuously improving process efficiency to drive down the cost of hydrogen production, ACS designs and produces anodes, cell components, stack hardware, and assemblies of PEM, Alkaline and Solid Oxide Electrolyzers.

Explore our range of hydrogen electrolyzer and fuel cell components and contact our team today to discuss custom solutions for your project.

PEM ELECTROLYZER COMPONENTS

ACS Industries leverages its extensive experience, efficient processes, and production scale to deliver cost-effective PEM electrolyzer components, as well as Alkaline, AEM, and Solid Oxide electrolyzer solutions. This includes the design and manufacturing of anodes, cell components, stack hardware, and complete electrolyzer assemblies.

We are a high volume, vertically integrated global manufacturer of key anode, cathode, and assembly components for PEM electrolyzers including:

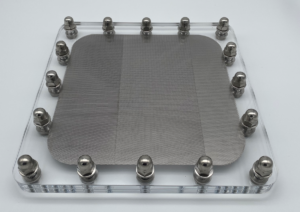

- Expanded metal flow field layer

- Novel alternative to sintered Porous Transport Layers (PTL), resulting in:

- Planar contact with coated catalyst membrane (CCM): surface roughness in the tens of nanometers, as opposed to traditional surface roughness of tens of micrometers in sintered PTL’s which provides:

- Increased efficiency

- Uniform catalyst utilization

- Longer-term operation without thinning of catalyst layer

- High differential pressure operation

- Fully controllable pore size and porosity:

- Possibility to create porosity gradient across PTL

- Higher in-plane and out of plane electronic conductivity

- Reduced layer thickness without decreasing lifespan or increasing part failure

- Lower tortuosity than sintered PTL’s

- Planar contact with coated catalyst membrane (CCM): surface roughness in the tens of nanometers, as opposed to traditional surface roughness of tens of micrometers in sintered PTL’s which provides:

- Stamped bipolar plates

- Stack hardware

- End plates

- Rods

- High precision flat plates

- Mass produced assemblies of these parts utilizing:

- Diffusion bonding

- Welding

Explore our range of PEM electrolyzer components and contact our team today to discuss custom solutions for your project.

ALKALINE ELECTROLYZER COMPONENTS

As the demand for clean hydrogen surges, ACS Industries is dedicated to supporting green hydrogen production by manufacturing high-quality alkaline electrolyzer components, as well as component solutions for PEM, AEM, and Solid Oxide electrolyzers.

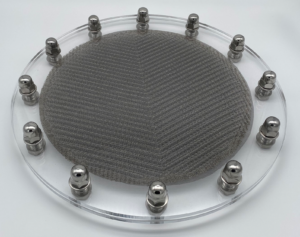

ACS produces a variety of components for alkaline electrolysis utilizing Knitted, Woven and Expanded Metal Mesh, including:

- Knitted Elastic Elements and Bubble Eliminators

- Twill Disks

- Nipple Plates

- Flynet Disks

- Expanded Metal Current Distributors

- Expanded and Woven Mesh Electrodes

We also offer the following value-added services to ensure that our parts are a perfect fit in any system:

- Welding

- Laser Cutting

- Flattening

- Industrial Cleaning

- Crimping

- Full Anode Assembly

- Advanced Product Testing

Our alkaline electrolyzer components are often used in applications where a high-purity and continuous supply of hydrogen is required. They are known for their efficiency and reliability and are used in various industries to support the transition to cleaner and more sustainable energy sources.

Contact Our Experts About Electrolyzer Components

If you are searching for a reliable source for electrolyzer components or would like to know more about our advanced solutions in the green energy sector, please contact us or fill out the form below.