CUSTOM METAL MESH SOLUTIONS FROM THE WORLD’S LEADING MANUFACTURER: 80+ YEARS OF EXPERTISE

ACS Industries – Enabling Noble Industries

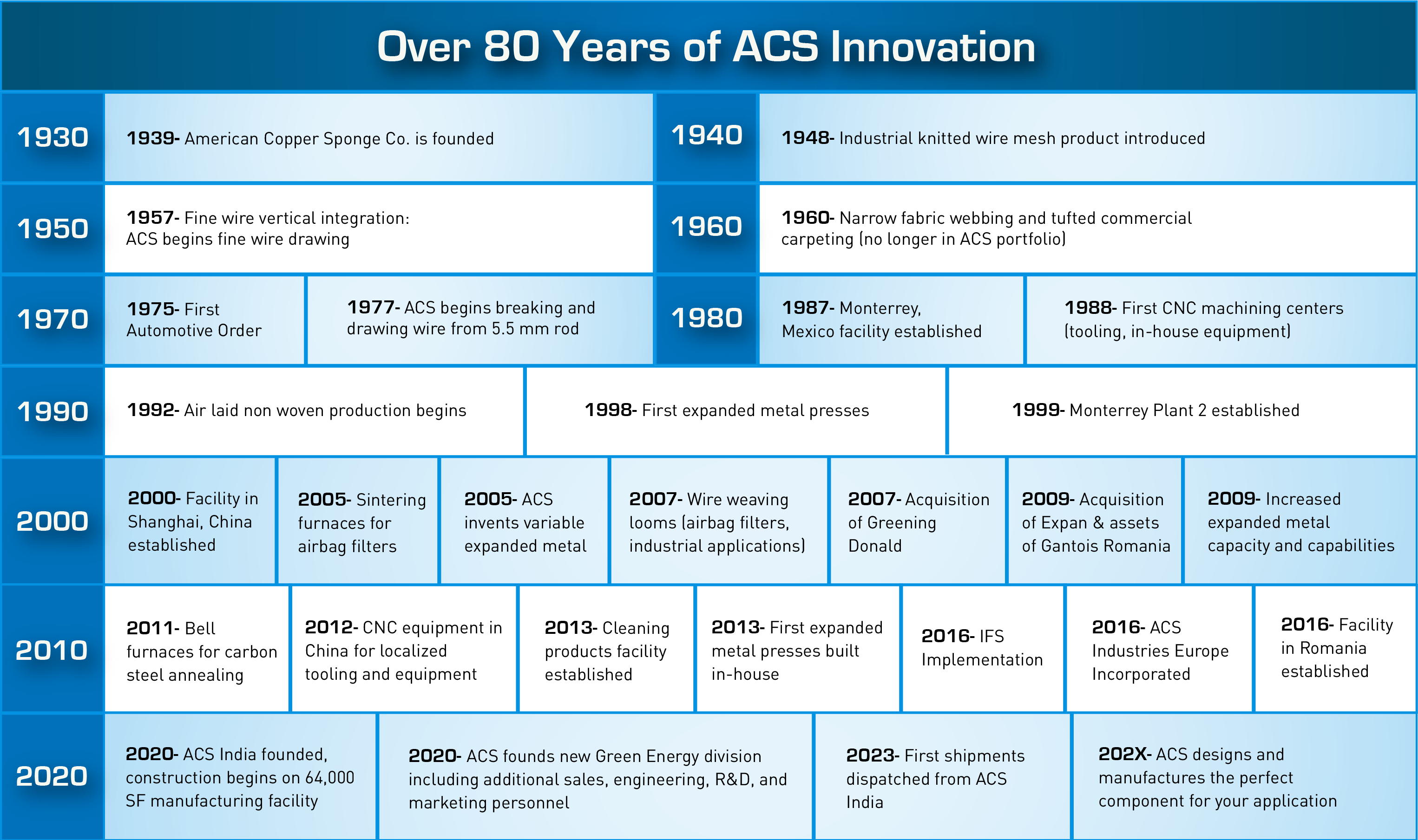

At ACS Industries, our history is built on engineering ingenuity and manufacturing excellence. Founded as American Copper Sponge in 1939 in Rhode Island, USA, we began by manufacturing knitted copper sponges. Seven years later, we introduced our first knitted wire mesh air and grease filters, which ballooned in popularity and in 1960 led management to rename the company to ACS Industries, Inc. to better reflect our expanding engineering focus.

Today, ACS is the world’s largest vertically integrated wire mesh manufacturer. From hydrogen energy systems to advanced filtration and automotive safety components, we deliver custom metal mesh solutions to OEMs and Tier 1 suppliers worldwide. Our global manufacturing footprint, in-house wire drawing capabilities, and commitment to quality position us as a trusted partner for engineered mesh components that meet the demands of tomorrow’s industries. Contact our experts to see how our solutions can optimize your project.

Our History of Growth

In the 1970’s, ACS began manufacturing an array of hot and cold end automotive exhaust products and has continued diversifying and innovating in this space ever since. Today, we are a key global supplier of pyrotechnic airbag inflator filters and exhaust systems components to both Original Equipment Manufacturers (OEMs) and Tier 1 suppliers. Our quality control measures and standards have been tirelessly honed throughout our extensive experience with these meticulous automotive industry clients.

ACS has undergone significant expansion over the years, establishing three production facilities in Monterrey, Mexico between 1987 and 2013, as well as new production facilities in Shanghai in 2000, Romania in 2016, and India in 2020. We also maintain sales offices across the United States, Germany, England, and more.

ACS expanded into nonwovens and cleaning supplies for the foodservice and janitorial industries in 1992 and now has a dedicated plant producing these materials in Monterrey, Mexico.

In 1998 ACS added expanded metal to our mesh manufacturing capabilities, completing the full range of commonly used forms of porous metal: knitted, woven, and expanded.

In 2020 ACS entered the green energy market, taking advantage of our expertise in various metal meshes and flow profiles to produce optimized components for hydrogen electrolyzers and other green energy equipment. Our world class R&D team is actively working on several initiatives centered around bringing down the cost of green hydrogen production, including a DOE grant-backed project to revolutionize PEM electrolyzer components.

ACS Core Values

Our core values aren’t just words; they guide every decision we make. From product innovation to customer service, these principles shape how we operate, collaborate, and deliver custom metal mesh solutions around the globe.

Contact Our Custom Metal Mesh Experts

Reach out to us today to learn more about our custom metal mesh manufacturing capabilities and services and how we can help you meet your unique requirements. We offer a wide range of expertise, from weaving and knitting, to wire drawing and heat treating, and can provide you with a complete solution for your custom metal mesh needs.