Automotive NVH Solutions

At ACS, our patent pending single-rivet heat shield isolator and production process are revolutionizing automotive NHV solutions by addressing isolation, vibration dampening, and harshness reduction in one integrated component. To improve existing assemblies, our innovative design eliminates both multiple-piece constructions and their costly manual assembly process.

What is Noise Vibration Harshness in Automotive Engineering?

Noise, Vibration and Harshness (NVH) describes the experience and measurement of unwanted sound and movement a vehicle or mechanical system produces during operation. Commonly used in the automotive industry, NVH testing evaluates how engine, road, and mechanical vibrations affect comfort, perceived quality, and system durability. These factors are influenced by everything from engine performance and road conditions to mechanical components and aerodynamic flow.

Often referred to as noise attenuation or vibration dampening, noise vibration harshness engineering focuses on controlling mechanical resonance, isolating high-frequency noise paths, and reducing vibration transmission.

Benefits of Automotive NVH Reduction

Improving noise vibration harshness not only contributes to a quieter experience, but also increases the perceived value of a product. Automotive manufacturers use a range of vibration dampening products and sound-deadening materials to:

- Reduce vehicle noise and harshness for a smoother, quieter driving experience

- Minimize vibration in engines, suspension systems, and cabin components

- Improve durability by protecting sensitive components from mechanical stress

- Enhance comfort and performance for both drivers and passengers

- Meet stringent OEM specifications for cabin noise levels

Effective automotive NVH solutions are essential in today’s vehicles, especially as electric and hybrid models demand even more precise sound control in the absence of traditional engine noise.

What is a Heat Shield in NVH Applications?

A heat shield is a protective barrier used in vehicles to guard key components from high temperatures produced by the engine and exhaust system. Depending on their purpose, whether to reflect, absorb, or disperse heat, heat shields are made from various materials. All types help extend engine lifespan, improve performance, and enhance safety by minimizing heat exposure to nearby parts.

In NVH applications, heat shields can also function as vibration isolators when combined with knitted wire mesh or other engineered materials.

ACS’ “One Piece” Isolator: A Key NVH Component

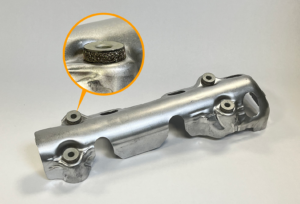

Our patented NVH One Piece heat shield Isolator is engineered to secure heat shields to components such as manifolds, turbochargers, and catalytic converters, while also providing noise, vibration, and harshness protection.

Unlike traditional isolators, which use two mechanically attached washers that can detach in transit, our solution forms the compressed knitted mesh directly to the heat shield. This integrated design withstands extreme temperatures beyond the limits of most elastomers and offers superior NVH dampening. The result is improved product integrity, reduced scrap, and greater automation compatibility.

ACS Automotive NVH Products & Technologies

As a trusted partner and supplier to some of the world’s largest automotive OEMs, ACS Industries offers a range of products for NVH reduction. In addition to our patent-pending single-rivet heat shield isolator, our proven solutions include:

- Knitted Wire Mesh: Provides superior vibration isolation and thermal shielding in exhaust and powertrain systems.

- Removable and Reusable Insulation: Designed for easy installation and long-term performance in high-temperature environments.

- Cold End Seals and Gaskets: Custom solutions that prevent exhaust leaks while minimizing vibration and harshness.

- Muffler Insulation: Enhances noise reduction and temperature control in automotive exhaust systems.

Our engineering team brings extensive experience and expertise to every project. With a commitment to innovation, we often provide unique automotive NVH solutions to reduce noise, vibration and harshness, enhance production efficiency and optimize end-product performance.

Whether you are improving vehicle acoustics, extending component life, or meeting strict industry standards, you can rely on our dedicated experts to deliver solutions that meet your requirements and improve operational success.

FAQs: NVH in Automotive Engineering

How does knitted wire mesh improve NVH performance in exhaust systems?

Knitted wire mesh provides a flexible yet durable interface between components, absorbing vibration energy and preventing metal-to-metal contact. In exhaust systems, it disrupts both structure-borne and airborne noise transmission paths.

What makes the ACS One Piece Heat Shield Isolator different from conventional NVH isolators?

Instead of relying on two mechanically attached washers, our isolator compresses knitted mesh directly into the heat shield, creating a single, integrated NVH barrier. This eliminates detachment risk, supports automation, and withstands extreme temperatures beyond elastomer limits.

Why is NVH reduction especially important for EVs and hybrids?

In the absence of engine noise, other sounds, like road noise, gear whine, and component vibration, become more noticeable. NVH solutions in EVs focus on isolating these sources without adding excessive weight or reducing thermal efficiency.

What testing methods are used to validate automotive NVH solutions?

Common methods include modal analysis, acoustic intensity mapping, and transfer path analysis. ACS components are engineered to perform under these test conditions, ensuring OEM compliance.

Request a Custom Automotive NVH Solution

If you are looking for noise, vibration and harshness reduction options for your automotive or industrial application, we are here to help. Reach out via the form below or call 1-866-783-4838. We look forward to discussing your specifications.