https://acsindustries.com/wp-content/uploads/2026/01/The-Parts-You-Dont-See-Blog-Thumbnail-Image.png

820

1184

Sean O’Riordan

https://acsindustries.com/wp-content/uploads/2025/01/ACS-Logo-for-Website-Header-01-300x133.png

Sean O’Riordan2026-01-27 20:04:032026-01-27 20:06:31The Parts You Don’t See That Make Modern Vehicles Safer and Quieter

https://acsindustries.com/wp-content/uploads/2026/01/The-Parts-You-Dont-See-Blog-Thumbnail-Image.png

820

1184

Sean O’Riordan

https://acsindustries.com/wp-content/uploads/2025/01/ACS-Logo-for-Website-Header-01-300x133.png

Sean O’Riordan2026-01-27 20:04:032026-01-27 20:06:31The Parts You Don’t See That Make Modern Vehicles Safer and QuieterWhy Choose ACS? – A Vertically Integrated Wire Mesh Manufacturer

Unmatched Breadth of Expertise

ACS boasts a wide range of production capabilities including: woven metal mesh, expanded metal, knitted wire mesh, wire cloth, sintering and brazing, crimping, wire drawing, annealing, stamping, and even part assembly. These sweeping capabilities paired with the valuable engineer engagement ACS brings to every one of our projects as a leading vertically integrated wire mesh manufacturer, allow us to provide parts and solutions that fit seamlessly into our clients’ manufacturing operations.

A Trusted Supplier with 85+ Years of Experience

Over the last 85+ years, ACS has been a respected supplier to some of the world’s largest automotive OEM’s and Tier 1 suppliers. We are the world leader in pyrotechnic airbag inflators and our automotive expertise also extends into hot and cold end exhaust components as well as an array of safety components. We have consistently surpassed the scrupulous standards that suppliers of this industry are held to, resulting in many multi-decade prosperous partnerships with clients.

World-Class R&D and Innovation

ACS maintains a state of the art R&D facility in Rhode Island, USA where we have developed many proprietary technologies including Variable Expanded Metal (V.E.M.) ™ metal expanders that apply intermittent changes in the dimensions of cuts to create variations in the open area that eliminate nesting when the material is wrapped to create layers. This automated process vastly improves final product performance as well as tight tolerance conformance while eliminating waste. ACS’s R&D team is actively working on several Green Energy initiatives including new technologies that bring down the cost of Hydrogen production.

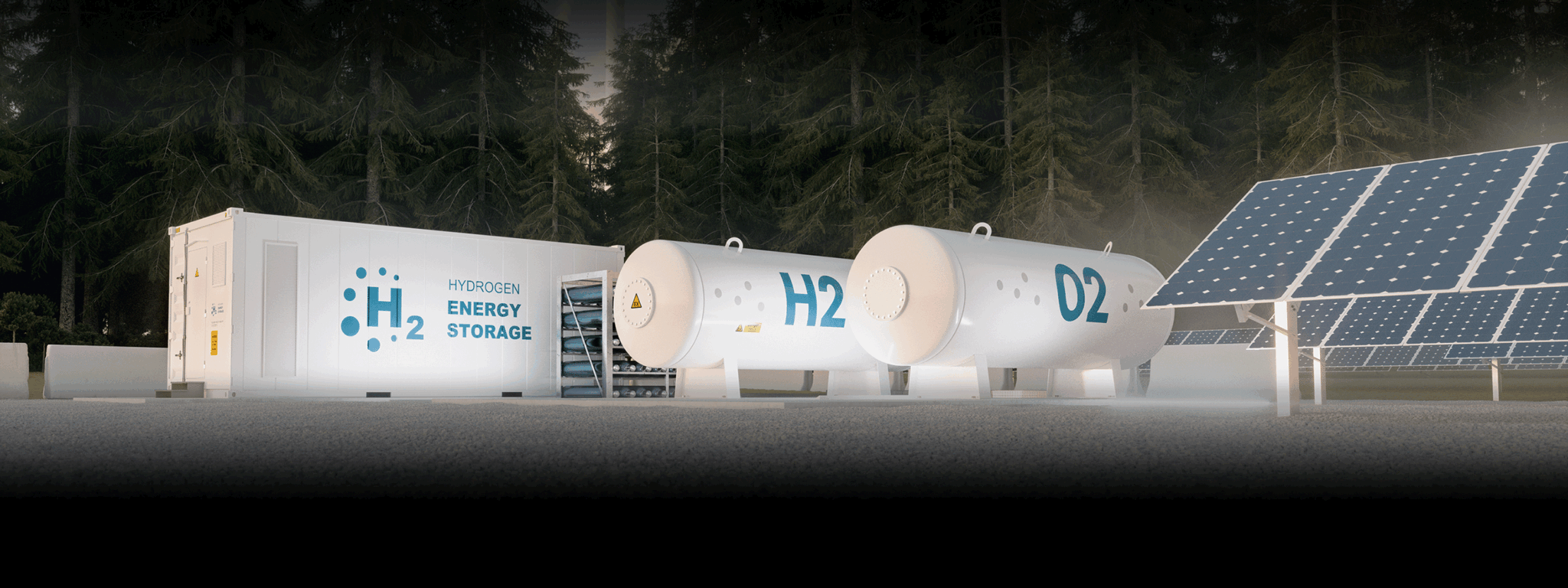

Advancing Green Hydrogen Technology

ACS is now leveraging our expertise in knitted wire mesh, woven wire, and expanded metal to support Green Hydrogen Production. ACS currently produces components and assemblies for both PEM and Alkaline Electrolyzers with more solutions on the way. Our novel 3D knitting process can cut down on materials and assembly time for alkaline electrolyzer construction by creating the optimal crimped knitted mesh layer with electrode layer knitted in. For PEM electrolyzers, we produce an alternative to traditional sintered porous transport layers consisting of high-throughput anode packs utilizing our MicroExpan ™ metal expanding technology for optimal performance. Our Green Hydrogen division is consistently finding new ways to apply our abundant engineering acumen to bring down the cost of hydrogen production.

ACS’ Global Reach

We offer rapid prototyping and have over 1,000,000 sq. ft. of manufacturing space across the globe, which allows us to scale new products smoothly from concept to mass production. As a vertically integrated wire mesh manufacturer, we ensure quality and efficiency throughout the entire production process. We have locations in Rhode Island and Texas, USA, as well as Romania, Mexico, China, India, and Germany with customer support representatives available in additional geographies. This means that wherever you are in the world, ACS has representatives nearby ready to begin solving for your manufacturing needs. Our global sourcing strategy allows us to always find the best raw material fit for any given project.

Dedicated Engineering Support for Custom Solutions

Our engineers bring a wealth of experience and know-how to the table. They get involved early in each of our projects, often making site visits to make sure ACS is producing parts and components that fit perfectly into both your manufacturing process and your finished product. The ACS Engineering Team can often find novel ways to eliminate waste, speed up production time, or improve end-product performance by going beyond the drawings and developing a deep understanding of our clients’ operations. Explore our innovative solutions.